In the fast-paced landscape of industrial goods, constant adaptation to emerging trends is crucial for businesses seeking sustained growth and competitiveness. The industrial sector, often regarded as the backbone of economies, has undergone significant transformations over the years. As we delve into 2024, several key trends are shaping the industrial goods sector, influencing everything from manufacturing processes to market dynamics. Let’s explore these trends in detail.

Digitalization and Industry 4.0

One of the most transformative trends in the industrial goods sector is the widespread adoption of digital technologies, often referred to as Industry 4.0. This paradigm shift involves the integration of smart technologies, the Internet of Things (IoT), and data analytics into manufacturing processes. Smart factories equipped with sensors and connected devices enable real-time monitoring and optimization of production, leading to increased efficiency, reduced downtime, and better resource utilization.

Digitalization also facilitates the implementation of predictive maintenance, where equipment health is monitored in real-time, allowing businesses to address potential issues before they escalate. This not only minimizes disruptions but also extends the lifespan of machinery, making operations more cost-effective and sustainable.

Sustainable Manufacturing Practices

The industrial goods sector is increasingly embracing sustainable manufacturing practices to align with global environmental goals and meet the rising demand for eco-friendly products. Companies are investing in cleaner and more energy-efficient technologies, reducing waste, and optimizing resource usage. From the use of recycled materials to the implementation of green energy solutions, sustainability is becoming a key driver of innovation in the industrial goods industry.

Consumers are now more environmentally conscious, and businesses that prioritize sustainability not only contribute to a healthier planet but also enhance their brand image and appeal to a growing market segment. As a result, sustainable manufacturing practices are no longer just a trend but a strategic imperative for long-term success in the industrial sector.

Advanced Robotics and Automation

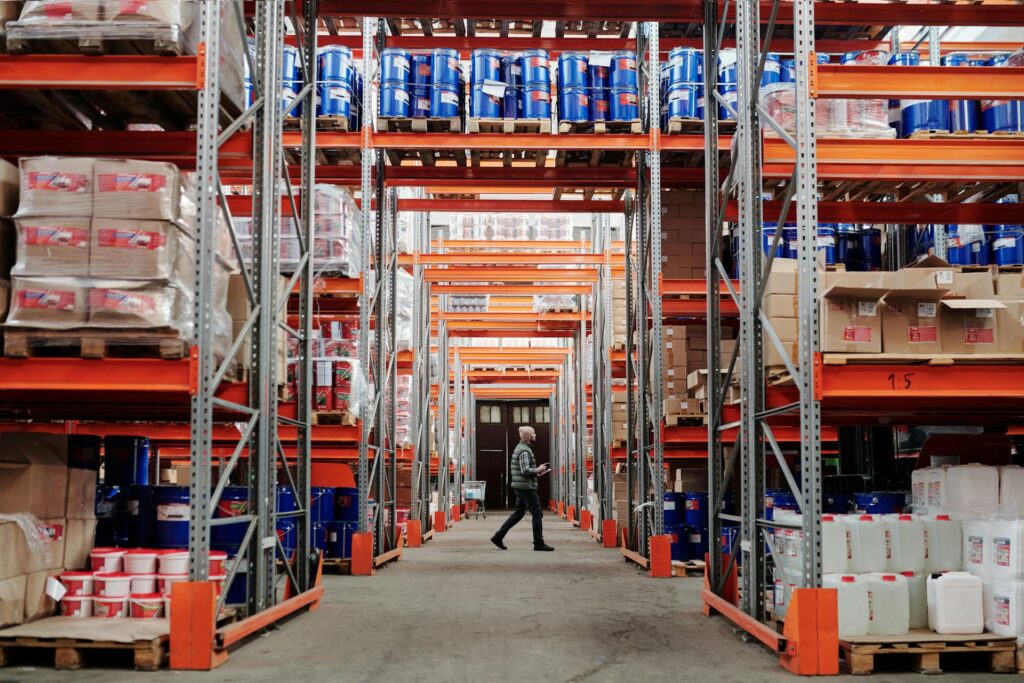

Automation has been a trend in the industrial sector for years, but recent advancements in robotics are taking it to new heights. From autonomous vehicles within warehouses to robotic arms on the production line, industrial automation is becoming more sophisticated and adaptable. Robots are not only performing repetitive tasks but are also increasingly capable of intricate operations, enhancing precision and speed in manufacturing processes.

The integration of artificial intelligence (AI) with robotics is another noteworthy development. AI-powered systems can analyze vast amounts of data to optimize production workflows, predict equipment failures, and make real-time adjustments. This not only increases efficiency but also allows human workers to focus on more complex and creative aspects of their roles.

Supply Chain Resilience

The disruptions caused by global events like the COVID-19 pandemic have underscored the importance of resilient supply chains. In response, industrial goods companies are reevaluating and reconfiguring their supply chain strategies to enhance flexibility and mitigate risks. This involves diversifying suppliers, embracing digital tools for real-time visibility, and employing predictive analytics to anticipate and respond to potential disruptions.

The trend towards supply chain resilience is driven by a recognition of the interconnectedness of the global economy and the need for businesses to be agile in the face of unforeseen challenges. Companies that prioritize supply chain resilience can better navigate uncertainties, ensuring a steady flow of materials and minimizing the impact of external shocks on their operations.

Customization and Personalization

Consumer expectations for personalized products are extending into the industrial goods sector. Increasingly, businesses are adopting flexible manufacturing processes that allow for greater customization of products to meet individual customer requirements. This trend is particularly relevant in industries where bespoke solutions are in high demand, such as aerospace, automotive, and industrial machinery.

The ability to offer customized solutions not only enhances customer satisfaction but also provides a competitive edge. Advanced technologies, including 3D printing and modular manufacturing, are instrumental in enabling this trend, allowing companies to efficiently produce small batches of highly customized products.

Cybersecurity in Industrial Environments

As industrial systems become more interconnected through digitalization and IoT, the risk of cyber threats becomes a critical concern. The industrial goods sector is recognizing the importance of robust cybersecurity measures to protect sensitive data, intellectual property, and critical infrastructure. A breach in cybersecurity not only jeopardizes the integrity of operations but can also have far-reaching consequences on a global scale.

To address this, industrial companies are investing in cybersecurity technologies and protocols, conducting regular audits, and implementing training programs to enhance the awareness of cybersecurity risks among employees. The emphasis on cybersecurity is crucial for maintaining the trust of customers, ensuring the reliability of operations, and safeguarding the industry from potentially catastrophic cyber-attacks.

In conclusion, the industrial goods sector is undergoing a profound transformation driven by digitalization, sustainability, automation, resilience, customization, and cybersecurity. Businesses that adapt to these key trends are not only better positioned to thrive in the current market but are also laying the groundwork for a more innovative, efficient, and sustainable industrial future. Staying ahead of these trends will be essential for companies seeking to navigate the dynamic landscape of the industrial goods sector in 2024 and beyond.